PDF Solutions

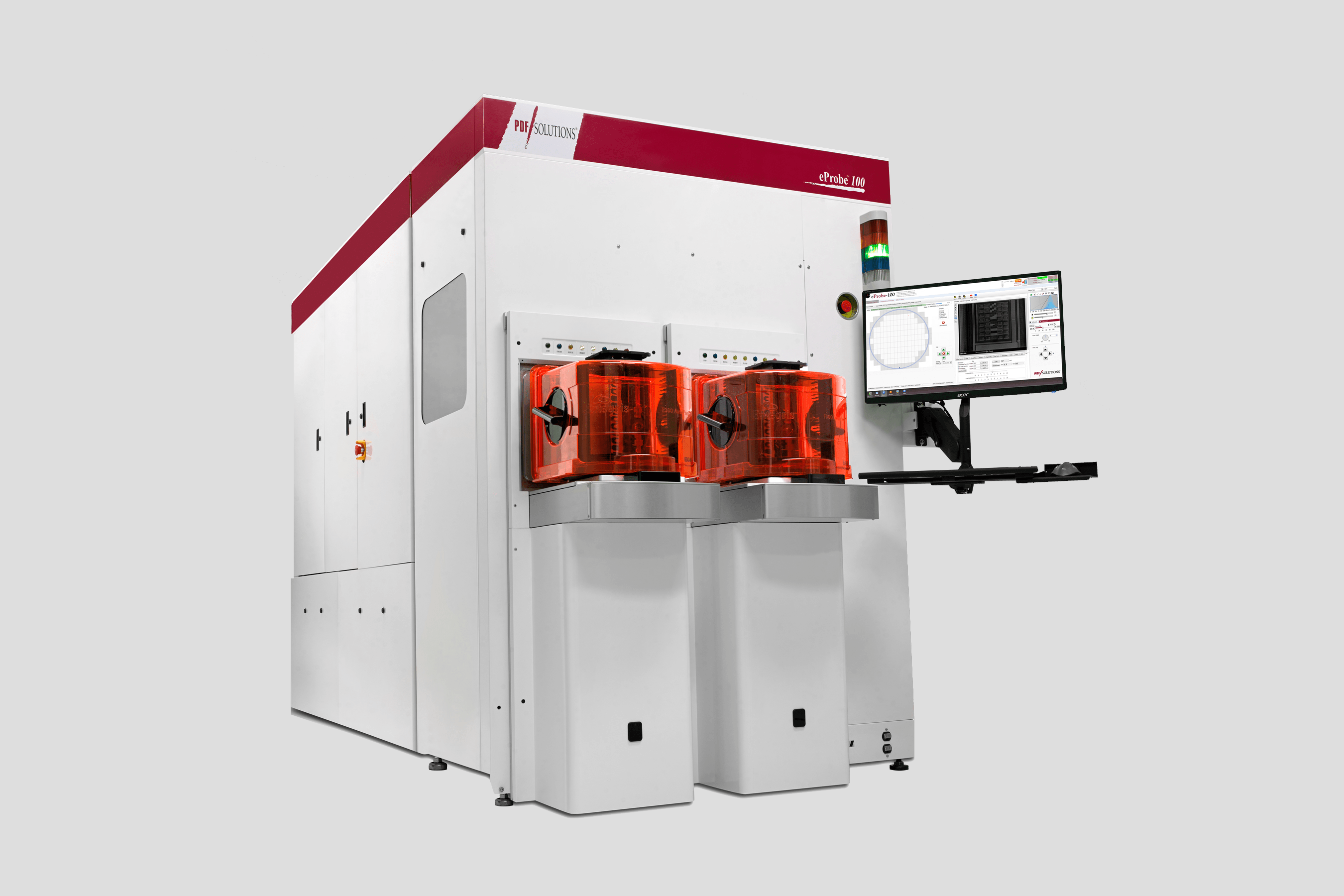

Scanning Electron Microscope for Semiconductor Tool

Challenge

Develop an advanced control system for an integrated circuit (IC) inspection tool consisting of a nanometer-precision scanning electron microscope (SEM) used to rapidly perform wafer metrology.

Services

Advanced control system development. FPGA programming. Algorithm development for image processing, calibration, and alignment. Ongoing design and development for continuous improvements to control automation, signal processing, and performance.

Outcome

Successfully shipped tool to customers. Next generation development and improvements spanning several years, with JKI collaborating to solve even the toughest challenges.

"We value our relationship with JKI because every time we face a challenge we know we can count on their highly skilled team to work collaboratively and solve even the toughest challenges. JKI has helped us accelerate our R&D, which has been critical to the successful development of our SEM tool."

Building A Next-Generation Scanning Electron Microscope to Streamline Semiconductor Manufacturing

By Yoram Schwarz, Project Manager, PDF Solutions and Sarah Zalusky, Senior Project Engineer, JKI

PDF Solutions, Inc. is a leading provider of yield improvement technologies and services for the integrated circuit (IC) manufacturing process lifecycle. At PDF Solutions, our goal is to develop systems that enable clients to lower the costs of IC design and manufacturing, minimize time to market, and improve profitability, even as the design process has become increasingly complex with advances in Moore’s Law and chip size reductions.

Recently, PDF Solutions has been working on a custom scanning electron microscope (SEM) that performs wafer metrology at various points during the manufacturing process to ensure non-destructive inline electrical characterization and process control. Our new system includes both the optical microscope, which uses images from a high-resolution camera, and the SEM, which produces an SEM image. One of the biggest innovations that differentiates our system from competing systems is that our images can be analyzed in real time instead of offline. For this real-time analysis to work properly, we need extremely fast scanning rates that can produce high-resolution images and measurements with nanometer precision. Our team knew NI LabVIEW system design software was the best tool for these enormous control challenges, and we also knew we would need help from the best LabVIEW software architects in the industry: JKI.

Challenge 1: Rapidly Acquire an Image to Validate Our Wafer Metrology Process

When we initially brought JKI into this project, we were working on the prototype of our system and wanted help acquiring high-resolution images with the SEM at extremely fast acquisition rates. In less than four months, JKI helped us accomplish acquisition rates of 250 MHz per pixel using an NI FlexRIO board and software developed using the LabVIEW FPGA module. By using LabVIEW for this part of the process, the PDF/JKI team was able to easily integrate our third-party FPGA IP and implement FPGA logic in a fraction of the time compared to alternative platforms.

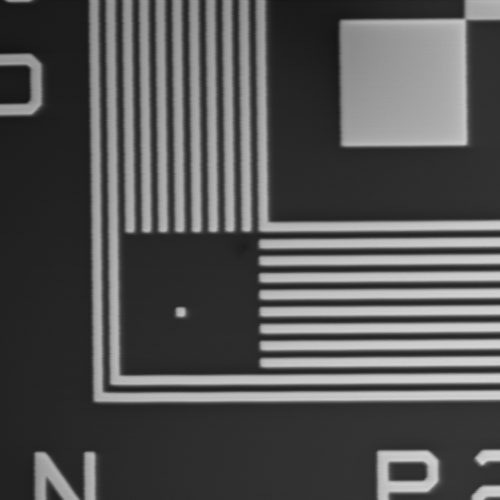

Challenge 2: Alignment and Autofocus on the Nanometer Scale

Each time a wafer is brought in for inspection, the orientation of the wafer needs to be precisely measured so that features on the nanometer scale can be identified. We call this process of finding the offset and angle of each wafer “alignment.” Whenever a new type of wafer is available, alignment on the first wafer must be performed manually so that an automated alignment file can be created. The PDF/JKI team developed a thorough manual alignment process that goes through several iterations using the SEM and optical microscope. When the alignment is perfect, an automated alignment file is created for future use. The alignment file relies heavily on image processing to identify known features at several locations on the wafer, and then uses those positions to calculate alignment values.

Focus quality is another important aspect of imaging with the SEM. Images must be properly focused so that they can be effectively used. Moreover, the focus must be adjusted dynamically because the various inspection areas on the wafer are not flat when analyzed at a nanometer scale. The PDF/JKI team put tremendous effort into creating a robust autofocus algorithm that can operate reliably under adverse imaging conditions (such as high noise and low contrast), and with a high degree of accuracy, for both the SEM and optical microscopes.

SEM alignment fiducial

Challenge 3: Putting it All Together

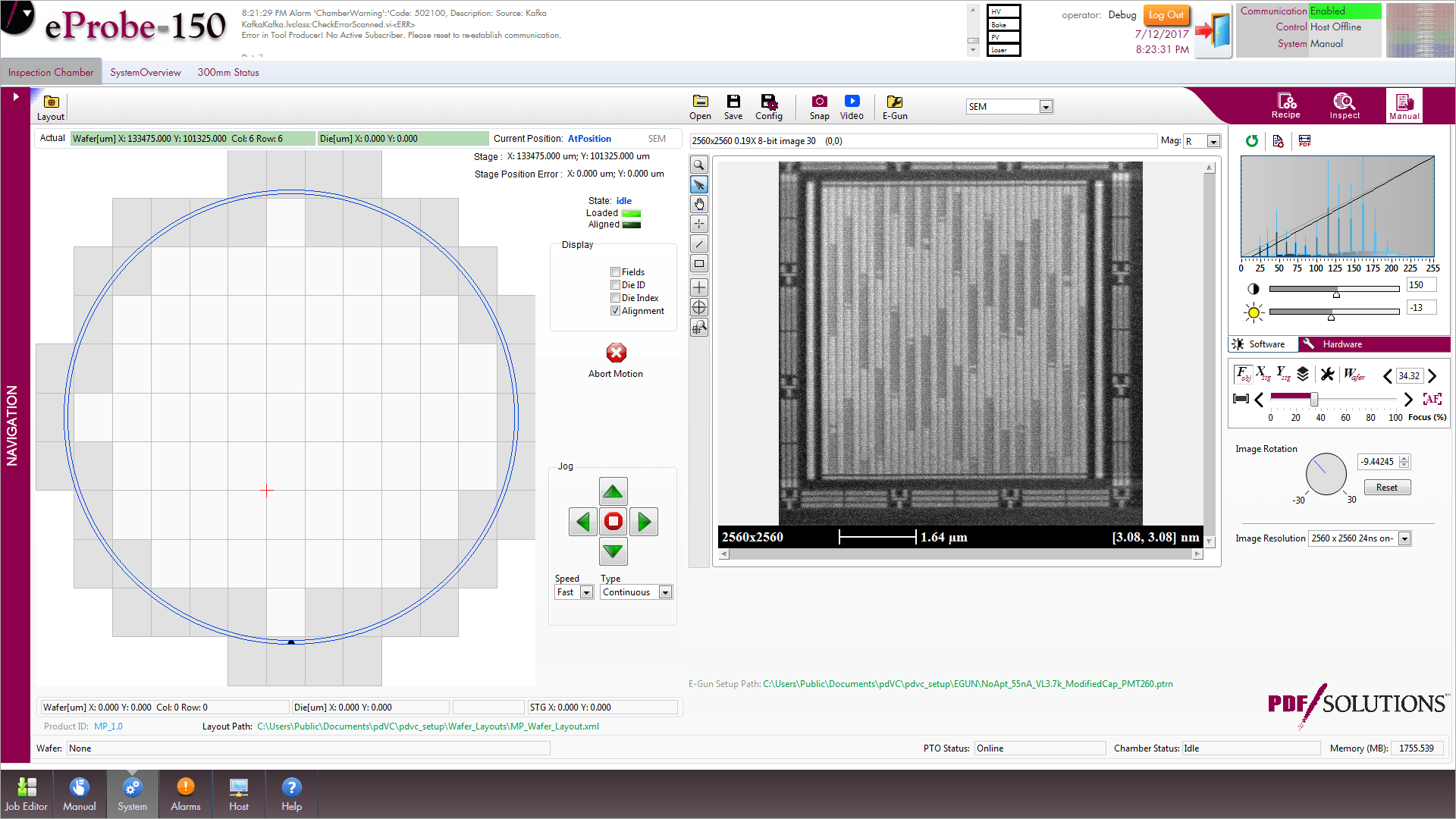

While LabVIEW provided the control for the components necessary to perform wafer inspection, the development of the frontend of the system was being performed by another member of our contract engineering staff using a C# application called the Peer Tool Orchestrator (PTO). We utilized JKI to develop an interface that would connect the frontend of our system to the backend.

On the backend, LabVIEW controls most of the components that perform the wafer inspection, including: controlling the x and y axis for the stage, sampling and driving various I/O points for the electron gun and the column, controlling the load port and equipment frontend module, and overseeing the vacuum and interlocking components. LabVIEW is also responsible for directing and managing the acquisition of both the SEM and optical images. JKI contributed to the software architecture design and the development of various high-level software components that coordinate the low-level hardware functionality, including data acquisition and image manipulation. This low-level functionality is necessary to perform wafer alignment and for the overall inspection to successfully take place.

We knew the integration between LabVIEW and PTO would be a complex task, and we provided little guidance to JKI regarding how the integration should be achieved. Despite this, and though no one at JKI had faced this kind of challenge before, they hit the ground running. Their team developed the entire application using the JKI Rapid Application Framework for LabVIEW (RAFL) and then built it into a .NET interop assembly that can be called by PTO.

eProbe-150 user interface

Future Development Plans

To progress with the advancement and fine-tuning of our SEM, we needed to gain a better understanding of how the system was being used in the field. We shipped the tool to two customers, and asked JKI to send a member of their team to work with each customer onsite. This onsite collaboration was an invaluable step and led to many ideas for ways we can further improve our algorithms to create a more robust and efficient next-generation tool.

We have worked with JKI for the past two years, and as we continue to advance our SEM system we anticipate that we will continue our partnership with them. We value our relationship with JKI because every time we face a challenge we know we can count on their highly skilled team to work collaboratively and solve even the toughest challenges. JKI has helped us accelerate our R&D, which has been critical to the successful development of our SEM tool.

*PDF Solutions, the PDF Solutions logo, and eProbe are registered trademarks of PDF Solutions, Inc. or its subsidiaries. Design-for-Inspection and DFI are trademarks of PDF Solutions, Inc. or its subsidiaries.

pdf.com

JKI is a National Instruments Certified Silver Alliance Partner.

JKI is a Xilinx Alliance Program Associate.

Download the PDF to print it and share it with your colleagues.

Scanning Electron Microscope for Semiconductor Tool

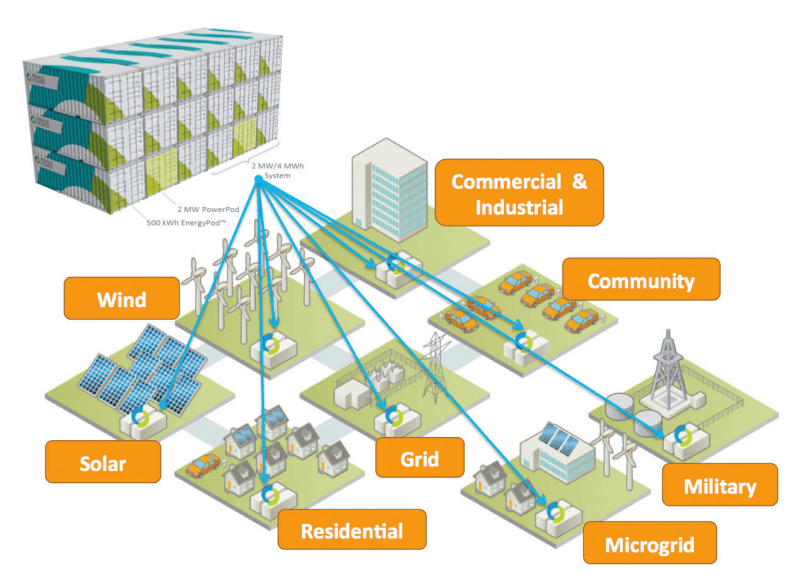

Megawatt Energy Storage Battery Controls and Power Regulation

If you liked the Scanning Electron Microscope for Semiconductor Tool Case Study you should also check out our Megawatt Energy Storage Battery Controls and Power Regulation Case Study.